Advantages of Electric Supercharging

There are certainly several reasons to consider electric supercharging for motorcycles. It can help create lighter, more compact bikes that handle with agility and ease. This technology could make a triple-cylinder motorcycle even lighter than standard literbikes, while still matching or even surpassing them in performance and rideability.

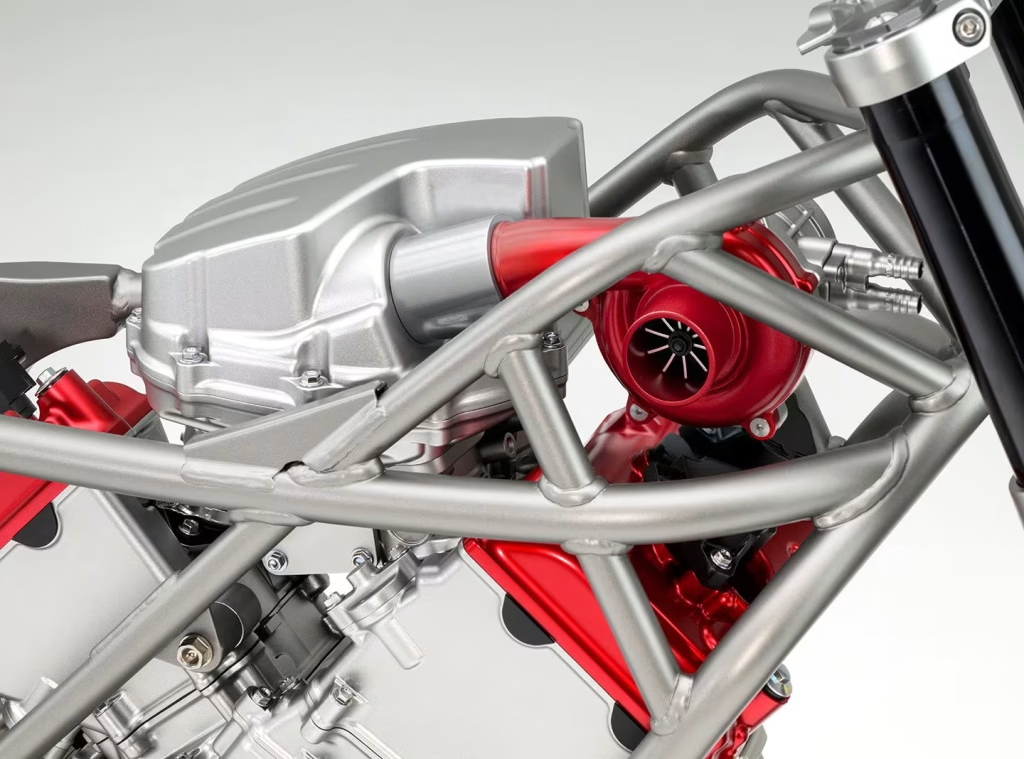

One example highlighting this is Honda’s electrically supercharged V-3 prototype, showcased at the Milan Show (EICMA). This compact engine is framed within a steel tube chassis, and it features a single-sided swingarm and high-performance male-slider fork. The two outer cylinders tilt forward, while the third tilts back at a 75-degree angle. Conventional throttle bodies, positioned under a cast aluminum plenum, receive boosted air from an electric-motor-driven centrifugal compressor just behind the steering head. Air enters on the right, with the electric motor on the left. Notably, two hose connections at the front of the motor hint at liquid cooling, and many components have been left exposed to display the essential structure of this concept bike.

History of Electric Superchargers

Electric blowers have a history of use in large marine diesel engines and Formula 1. Ships, with substantial electric power needs, often used electric blowers to capture unused exhaust flow. Formula 1 also found value in electric blowers to boost low-end torque faster than a turbocharger could.

Electric supercharging has also been introduced to production vehicles. In 2014, Mark Glasson of Valeo North America said, “The electric supercharger answers the low-end torque question, which a turbocharger does not.” Valeo, a French automotive supplier, provided Honda with an electric blower for the NSX entered in the Pikes Peak International Hill Climb that year.

Electric superchargers are now supplied by multiple manufacturers for automobiles. According to Mitsubishi Technical Review, some systems can reach 90% of their maximum speed in just 0.3 seconds, drawing up to 5kW of power. In some cases, such systems can run at full power for 30 seconds, or at about half power continuously. High-voltage systems (48V) are often required due to thermal limits on motor windings.

The switched reluctance motor (SRM), which lacks both windings and magnets, is a common choice in this application due to its high-speed durability and cost-effectiveness. With windings in the stator, liquid cooling is straightforward.

Honda V3 Engine with Supercharger

The two hose outlets on the front of Honda’s supercharger appear to be liquid cooling passages for the electric motor. Since electric torque is nearly instant, maintaining constant intake boost from idle to redline is straightforward with minor engine-management adjustments. A flat torque curve is feasible with precise software control of boost levels.

At the Milan Show, sources suggested the engine’s capacity is around 850cc. With dual overhead cams (DOHC) and four valves per cylinder, this middleweight engine could generate literbike-level power with a 5 psi boost, possibly reaching up to 140 horsepower.

Unlike the old turbocharged CX500, which sometimes lacked smooth throttle response, electric systems offer precise and controllable boosts. As a result, torque can be smoothly delivered without unpredictable “turbo lag.”

Power and Weight Requirements

An electric supercharger for a motorcycle would need much less power than automotive units, perhaps around 1,700W—easily within reach given the 1,550W output of some Honda alternators. Weight is also expected to scale down. In cars, these systems add around 22 pounds, so motorcycle-specific systems should weigh even less.

A smaller compressor rotor on motorcycles should allow faster spin-up, similar to the 0.25-second response seen in some automotive systems.

**Boost Limits and Design Considerations**

Excessive boost can risk destructive combustion (detonation), which is why high-boost engines generally have lower compression ratios. However, lower compression in everyday use can reduce efficiency. Three-cylinder designs can also help manage emissions by minimizing the total sealed length of the piston ring. This design reduces unburned hydrocarbons, which contributes to lower emissions.

In summary, the instant torque provided by electric supercharging can smooth out throttle response compared to traditional turbocharging, which relies on exhaust pressure. Honda’s plans for further development indicate that they aim to bring this exciting technology closer to mass production.

Your place is valueble for me. Thanks!…

Woah! I’m really digging the template/theme of this site. It’s simple, yet effective. A lot of times it’s difficult to get that “perfect balance” between user friendliness and visual appearance. I must say you’ve done a great job with this. Additionally, the blog loads extremely fast for me on Safari. Excellent Blog!

Hi there, I do believe your web site may be having

internet browser compatibility issues. When I take a

lookk at your site in Safari, it looks fine however, if opening

in IE, it has some overlapping issues. I merely wanted to give you a quick heads up!

Besides that, fantastic blog! http://Boyarka-Inform.com/